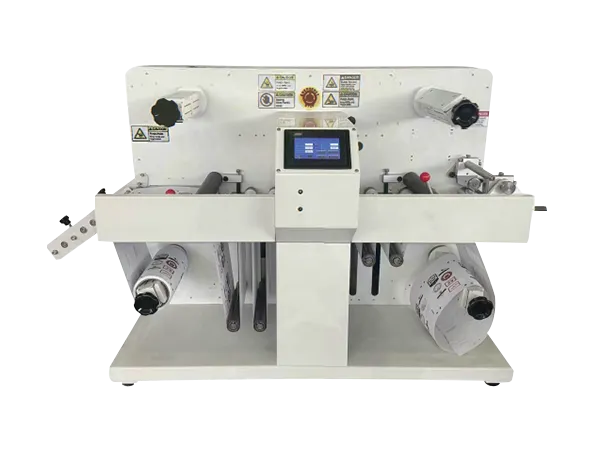

Drip Coffee Packaging Machine (Advanced Type)

Ultrasonic sealing and packaging machine for packaging drip bag coffee

Drip Coffee Packaging Machine (Advanced Type)

Ultrasonic sealing and packaging machine for packaging drip bag coffee

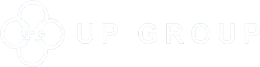

Our latest drip coffee bag packing solution is designed to pack various types of drip coffee bags, including standard, non-woven, and VFR. This packaging system uses fully ultrasonic sealing for the inner bags, offering superior packaging performance compared to traditional heat-sealing methods. The specialized slide doser weighing system minimizes coffee powder waste, ensuring both efficiency and accuracy.

| Working Speed | Approximately 50 bags/min |

| Bag Size | Inner bag: L90mm×W70mm Outer bag: L120mm×W100mm |

| Sealing Method | Fully 3-side ultrasonic sealing 3-side heating sealing |

| Weighing System | Slide doser |

| Weighing Range | 8-12grams/bag (based on the material’s proportion) |

| Filling Accuracy | ±0.2 grams/bag (depending on the coffee material) |

| Air Consumption | ≥0.6MPa, 0.4 m³/min |

| Power | 220V, 50Hz, 1Ph |

| Weight | 680kg |

| Overall Dimensions | 1400mm×1060mm×2691mm |

- The program has been optimized for better overall performance.

- The bag former is updated with a Teflon coating on the inner bag former to prevent coffee powder from sticking, ensuring accurate weight.

- An additional lamp has been installed for the outer bag device.

- A vibrating device has been added for feeding and the inner bag former, ensuring smooth coffee powder flow and preventing sticking.

- Additional nitrogen gas tubes have been incorporated for the inner bag forming section to maintain coffee freshness for a longer period.

- The outer bag film device has been slightly modified for improved functionality.

- The working efficiency is higher than conventional models available in the market

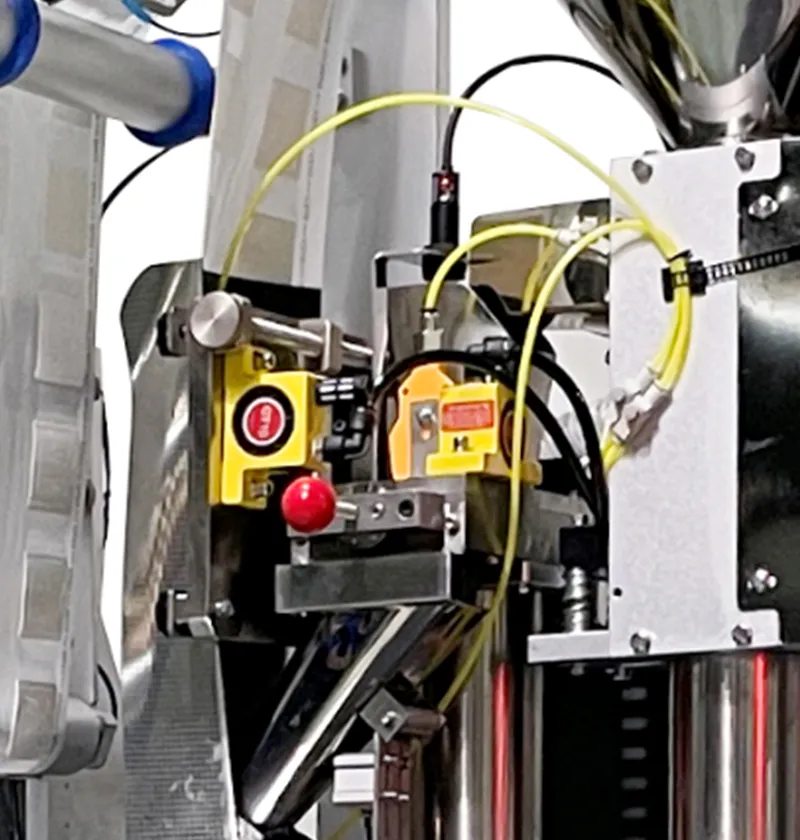

- The three-side ultrasonic sealing device for the inner bag ensures excellent packaging performance

- High accuracy with a margin of ±0.2 grams per bag

- An automatic air pressure detection device ensures reliable operation

- Equipped with a multifunctional sensor system that includes alarms for no coffee material, no packing material, eye-mark detection, empty inner bag, inner bag connection, and outer envelope eye-mark

- Enhanced safety with a guard device